© Fabian Schmid

© Fabian Schmid

© Fabian Schmid

© Fabian Schmid

© Fabian Schmid

To this day, 3D printing processes have hardly been able to establish themselves in series production, although they bring incredible advantages in terms of sustainability, product price, logistics and product diversity. This is because today's processes are either too expensive, too slow, or the materials and their surface quality are not convincing enough. The situation is different when printing damp clay, which is later fired into ceramics.

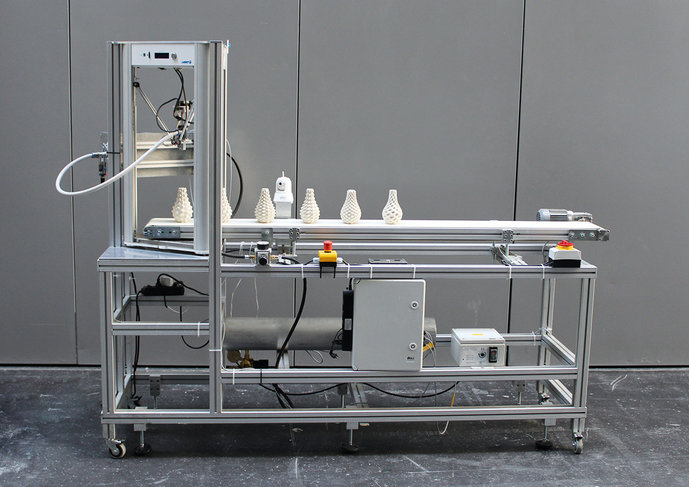

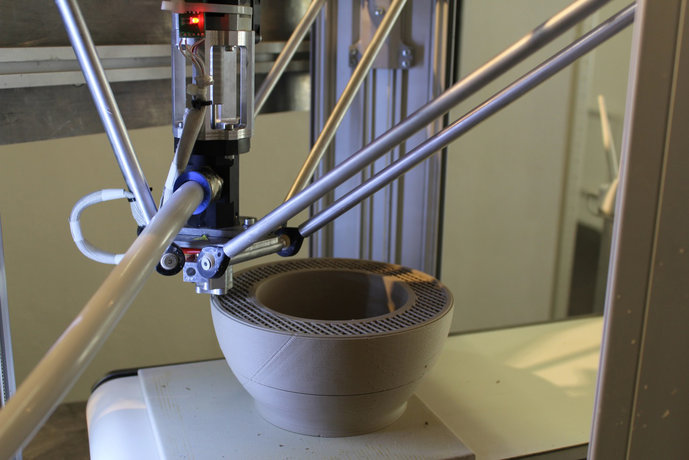

Fabian Schmid developed a sophisticated digital production system for ceramic objects for his diploma thesis. For over a year he worked on the construction of a suitable 3D printer and on the digital design of the products. Thanks to his printing system, he was able to drastically shorten, increase flexibility and automate printing times, making the whole thing economical. Its specially developed clay mixture with purely natural additives means it can ensure an even surface that will later be refined with glazes. Since the traditional industrial production of ceramic products is time- and effort consuming, Fabian Schmid's system offers a real alternative. Added to this are the unique possibilities 3D printing can offer. Inclusions, undercuts and complex structures can be easily realized, creating completely new ceramic products.

For his diploma, Schmid decided to develop a vase series that cannot be produced using any other method and incorporates the characteristics of 3D printing; this is how the "Skin" series came about. Parts of the outer shell were removed after the printing, thus exposing the delicate structure of the printing. The combination of technology and hand work preserves the character of manufacturing as a process thus creating unique objects. To present an additional facet of 3D printing, Schmid developed the "Surface" vase series. Here, it was important to him that the machine he developed enabled individual series production. Schmid attempts to give the concept of series production, which has so far been negatively connoted in industry, a completely new meaning. For this purpose, he developed a program that autonomously generates various surface shapes and projects them onto a base form. With this method, individualized products can easily be created.

While digital developments of the 21st century could hardly gain a foothold in the industry, the diploma project tries to combine traditional craftsmanship with the current technical possibilities.

Tutors: Prof. Volker Albus, Prof. Jürgen Walter (HS Karlsruhe)